Production

We all have a part to play in reducing environmental impact. We collect data from our key suppliers to understand how we can minimise our sustainable footprint. The factories that we work with meet our ethical and technical requirements before any orders can be placed.

Our Ethical Trade Team and our Code of Conduct

At Tu, there are dedicated ethical trade teams in the UK and our four Asia sourcing offices (Hong Kong, Shanghai, Dhaka and Delhi) who have responsibility for everyday management of ethical issues. They work to support our suppliers by conducting site visits, advising on best practice and training our suppliers.

We set out our expectations for suppliers on how workers are treated in our Policy on Ethical Sourcing, our contractual terms and our Supplier Handbook. Our Supplier Code of Conduct is aligned with the Ethical Trading Initiative (ETI) Base Code. Our code covers 13 key principles, including prevention of child labour, providing safe and hygienic working conditions, payment of a fair wage (national minimum wage being the minimum) and freedom of association. You can find a copy of our current policy here.

We pride ourselves on having good supplier relationships and work with them to ensure our high standards are met wherever we are sourcing from. Ethical and sustainable trading is a key part of this relationship. We work to train suppliers on ethical trade and engage with key suppliers on projects designed to improve worker welfare.

Before production

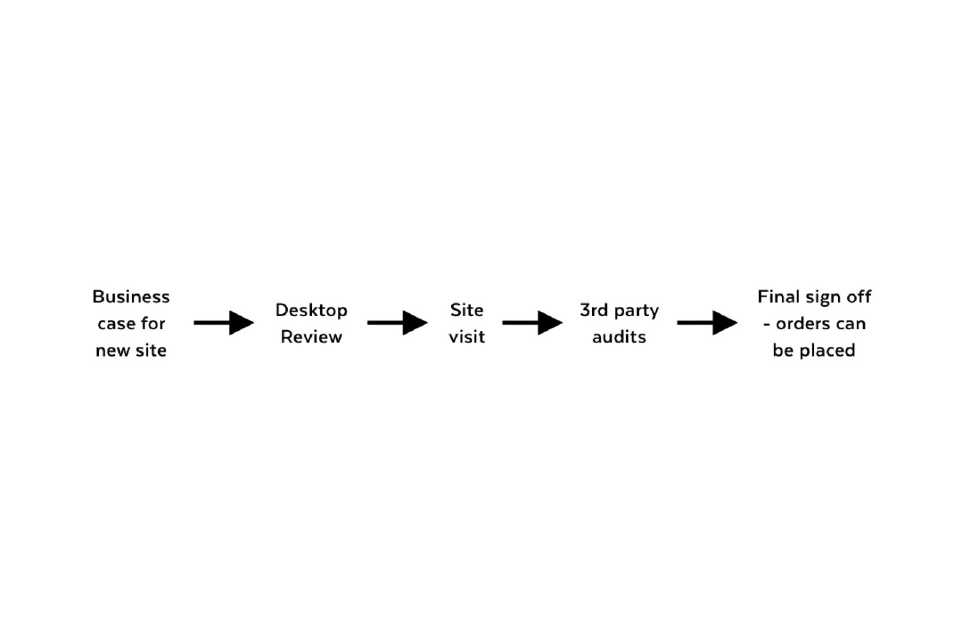

We have developed a three gate process that all factories need to go through in order to be approved for Tu production. We conduct this due diligence to give us confidence that we are placing new business with factories that uphold our standards and share our values. This gated process includes a site visit, an internal desktop review and a third party ethical and technical audit. It is only once the factory has been signed off that an order can be placed.

Ongoing site management

Every year we conduct independent, third party ethical audits as well as our own on site visits from Sainsbury’s colleagues. 100% of Tier 1 sites (which we define as making whole/finished products carrying a Tu label or are identifiable as a Tu product) that we work with must conduct an annual semi announced SMETA (Sedex Members Ethical Trade Audit), one of the most widely used ethical audit formats in the world. These audits need to be conducted by one of our selected audit bodies and must cover the whole site. The audit is then uploaded onto Sedex and shared with Sainsbury’s . If the audit result does not meet our requirements then the site will be asked to improve and action feedback within a set timeframe.

If child labour is found at a site supplying products to Sainsbury’s Argos, we will work with the supplier, site and our nominated appropriately qualified organisation to develop a solution that is in the long-term interests of the child or children involved. For more information, view our policy here.

Collaboration & best practice

Where possible we collaborate with selected third parties, other brands and organisations to ensure that we are continually improving our processes and the standards in our supply chains. Some of the existing relationships that we have can be found below.

Bangladesh Accord - The Accord is an independent, legally binding agreement between brands and trade unions to work towards a safe and healthy garment and textile industry in Bangladesh. Sainsbury’s has been a member of the Accord since it launched in 2013. It’s purpose is to enable a working environment in which no worker needs to fear fires, building collapses, or other accidents that could be prevented with reasonable health and safety measures.

Ethical Trading Initiative - We are founding members of the Ethical Trading Initiative (ETI), working closely with suppliers, non-profit organisations and unions to develop innovative responses to worker exploitation and forced labour. We participate in a number of ETI working groups focusing on particular supply chains where there are opportunities to improve working conditions through collaboration.

Textiles 2030 – We are signatories to WRAP’s Textiles 2030 initiative, which brings together businesses to collaborate on carbon and water targets, and contribute to discussions around policy development for textiles in the UK. Each year we submit our fibre tonnage data and receive an individual report allowing us to interrogate the impact of our sourcing, manufacture, and design.

Where do you source from?

We source Tu clothing from 15 countries around the world and we work with over 300 sites. If you would like to know more about where our Tu products are made we have published a list of our Tier 1 sites with information including address and number of workers. You can view the list here (pdf) or download it here (excel). This list will be updated every 12 months. Our factory disclosure is also available on the Apparel Coalition Registry and you can read more about the importance of supply chain transparency for Sainsbury’s here.

Cascale – The Higg Index

We recognise the importance of reducing our environmental impact and doing this collaboratively as an industry. In 2019 we became members of the Cascale. At Tu, we share the SAC's vision of an apparel, footwear, and textile industry that produces no unnecessary environmental harm and has a positive impact on the people and communities associated with its activities. Our membership of the SAC gives us access to a suite of measurement tools called the Higg Index. We started to roll out the Higg Facility Environmental Module (Higg FEM) to Tier 1 suppliers throughout 2019.

In 2023, 100% of all clothing sites are now on Higg. We will continue the rollout of the Higg FEM and use the data we receive.

To understand our environmental metrics and environmental risk within our supply base and work towards reducing our impact on the environment with our sites.

The Higg FEM measures:

- Environmental management systems

- Energy use and greenhouse gas emissions

- Water use

- Wastewater

- Emissions to air (if applicable)

- Waste management

- Chemical use and management

?$sfpoi:$sfcenter}&sm=aspect&aspect=2:1&sfcenter=center&sfpoi=poi&qlt=50&fmt=auto&noiser=0&fmt.jpeg.interlaced=true&fmt.jp2.qlt=40&w=600&)

?$sfpoi:$sfcenter}&sm=aspect&aspect=2:1&sfcenter=center&sfpoi=poi&qlt=50&fmt=auto&noiser=0&fmt.jpeg.interlaced=true&fmt.jp2.qlt=40&w=600&)

?$sfpoi:$sfcenter}&sm=aspect&aspect=2:1&sfcenter=center&sfpoi=poi&qlt=50&fmt=auto&noiser=0&fmt.jpeg.interlaced=true&fmt.jp2.qlt=40&w=600&)

?$sfpoi:$sfcenter}&sm=aspect&aspect=2:1&sfcenter=center&sfpoi=poi&qlt=50&fmt=auto&noiser=0&fmt.jpeg.interlaced=true&fmt.jp2.qlt=40&w=600&)